Griffin Moe

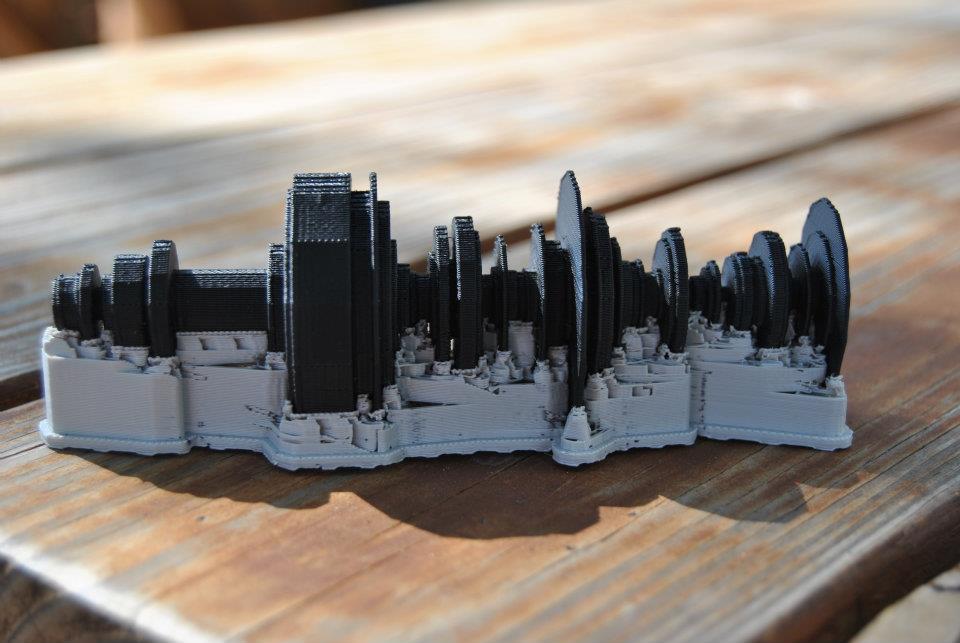

3D Printed Audio Waveforms

Instructables is a fantastic place to lounge around in. It was in their email newsletter that I saw this project and loved the idea of taking a sound and giving it tactile presence and to see the dynamics of a favorite piece of music. At first I just wanted to recreate the Instructables project as a gift but I knew that assembling small paper discs would be a pain, and paper was not going to be a tough enough material. After stowing the thought away for a while, I realized I had all of tools available to develop this individual’s idea into another direction.

At Heartland Community College I have access to CNC lathe and a 3D printer with no restrictions other than myself. For those who are not so familiar with the CAD world, a 3D printer does exactly what an ink and paper printer does except in three dimensions. In practice, a 3D shape is created by a technical artist and is given worldly shape by the 3D printer through the medium of ABS plastic . My alternative to the printer is the CNC lathe, which is like a normal lathe except it is completely controlled through computer instruction. I had some prior experience with the printer so I started out by studying it and writing some code in Processing, which would play back a WAV file and use the buffer levels to determine the radius of each cylinder slice just like on the Instructables project. Rather than creating paper cylinders, the end result of the program is an STL file ready to be sent to the printer. The completed waveform is actually black, the grey material on the bottom is created automatically by the printer and is used as support to print the main plastic. The support material is designed to be broken away, but I left it attached because it left me with a handy stand with no additional effort.

There are a few problems with using the 3D printer as there is only so much available space available the on the printer, which affects the scale and accuracy of the print. My next project is to use the CNC lathe and convert my code to output GCode, which can give me increased accuracy, beautiful smooth steps in between cylinders, and solid aluminum waveform. Unfortunately there are no easy Processing/Java libraries for GCode, which means directly controlling the lathe movements instead of just feeding data points into the printer. I do not have any experience using a normal lathe, let alone a CNC lathe, so it might be one of those fanciful ideas that never comes to fruition.